A Mill Test Certificate (MTC), or Mill Test Report (MTR), is issued by a manufacturer to certify the chemical and mechanical features of a product and its compliance with the applicable standards and technical specifications.

The first step before reviewing an MTC is learning what material has been selected for the design. The materials are typically defined in the drawings bill of materials (BoM) and/or project specifications. Once the type of material is known, the next step is reading the standard that defines the mechanical and chemical properties of the material.

Materials standards have identification systems for all the different products included in the document. In the steel industry, the most common identification is the steel grade which represents the steel plate, bar, pipe, or shape yield strength. The identification systems also include subcategories for those materials that require enhanced properties for specific service conditions. These subcategories are usually called class, type, category, etc. It could be the case that the drawing or project specification does not fully identify the material as per the standard. In such cases, it is recommended to reach the Engineer to confirm what type exactly has been included in the design.

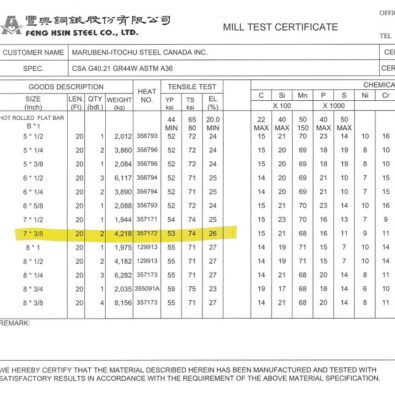

Once the material identification is known, reviewing the MTC is a matter of comparing the MTC to the material standard. The review exercise should confirm that the product included in the submitted MTC has:

- An identification that matches the ones defined in the drawings or spec and standard (i.e., grade, type, class, etc.);

- A geometry that matches the ones defined in the drawings or spec and standard (i.e., thickness, diameter, etc.);

- Mechanical properties that meet or exceed the standard requirements (i.e., yield, tensile strength, elongation, etc.); and

- A chemical composition that meets the standard ranges for each component.