ENGINEERING Services

ENGINEERING

Services

Corrosion Protection

According to industry studies, annual corrosion costs are approximately $2.5 trillion, or nearly 3.4% of the world’s GDP. Corrosion protection plays a critical role in the life cycle cost of any physical asset. All materials are subject to oxidation or weathering. A solid corrosion protection plan is fundamental to extending the durability of new or existing structures.

Our engineers and inspectors are certified by AMPP, the Association for Materials Protection and Performance (formerly NACE), and have extensive experience protecting municipal, industrial, commercial, marine, mining, oil, and gas infrastructures.

Helping our clients protect their new assets and extending the life of deteriorated structures is our passion. Tell us what you want to protect, and we will design a corrosion protection plan aligned with the environment’s corrosivity and your service life target.

Conceptualization

Prepare for a successful project

- Engineering support and consultation

- Corrosion studies

- Condition assessment of existing structures

- Design durability assessments

- Project technical specifications development and review

- Coating and lining selection

- Surface preparation and application methods

- Training

Construction

Ensure your project goes as planned

- Shop and field inspections

- Non-destructive and destructive testing

- Quality management plans

- Audits and first article inspections

- Inspection and test plans

- Preparation and review of technical documentation

Maintenance

Extend your asset durability with proactive maintenance

- Corrosion mapping and monitoring

- Cathodic protection surveys

- Periodic inspections

- Maintenance and repair plans

Metallurgy

Metallurgy

Understanding the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures (i.e. alloys) is fundamental to assessing the right materials for your projects. Equadron expertise includes a vast array of applications due to our thorough understanding of how the materials will perform in their specific environment.

New alloys are continuously developed to provide the longest service in adverse conditions. Selecting the right material for a project is a key step in new construction design. For existing infrastructure, we help our clients identify the installed materials’ grade, condition, chemical and mechanical properties, and prepare repair procedures to extend the service life of their assets. Our clients benefit from our materials suitability analysis and prevention of potential failures caused by manufacturing defects, improper selection of materials, fatigue, overloading, or corrosion.

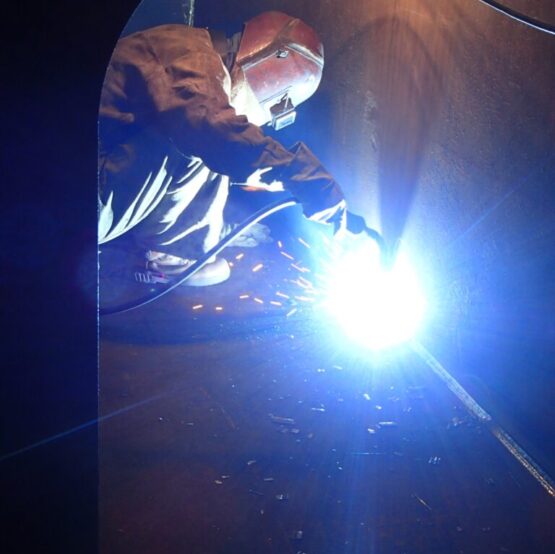

WELDING

WELDING

Equadron’s welding department is propelled by licensed engineers and inspectors certified by the American Welding Society (AWS) and the Canadian Welding Bureau (CWB).

Our welding engineering team provides solutions to solve technical challenges during the conceptualization, design, construction, inspection, and testing of any type of metal structure.

Equadron’s welding engineers assist in the base metal selection, writing and qualifying welding procedures, qualifying welders, addressing the cause and correction of defects, and preparing repair procedures.

Additional welding engineering services include pre-production, production, and post-production weld consulting utilizing codes and standards for numerous industrial applications.

Equadron welding engineers prepare project-specific welding specification which defines welding and fabrication requirements for processes, materials, procedures, qualifications, codes and standards, workmanship, inspection, testing, quality, and procurement. Solid welding specifications are the foundation of successful steel and miscellaneous metals projects. Equadron’s proactive and cooperative approach minimizes the likelihood of confusion and reworks by discussing project key variables with asset owners, engineers, and contractors as well as writing specifications with clear roles and responsibilities.

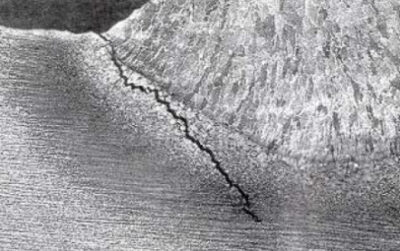

troubleshooting material failures

Forensic failure investigation, insurance investigations, litigation support, and expert witness testimony.

Equadron Consultants Inc. © 2023 – All rights reserved.