The welding consumables identification system is not the simplest to interpret. Sometimes, key welding project requirements are missed due to the complexity of their identification systems and the absence of handy instructions. In this article, we discuss the identification system of the most common welding processes in the steel industry.

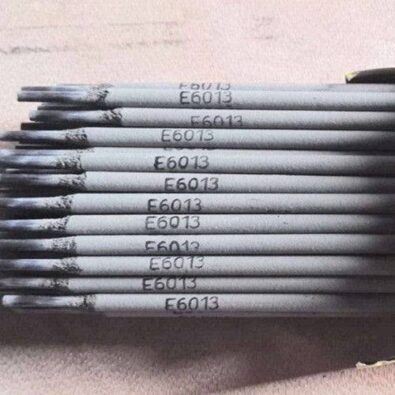

Shielded Metal Arc Welding (SMAW or stick)

E4918

E: arc welding electrode

49: Minimum tensile strength of deposited weld metal in the as-welded condition, in units of megapascals divided by 10 (490 MPa). It also designates a minimum elongation of 22%.

1: welding positions in which the electrode may be satisfactorily operated. In this case, 1 means all positions except vertical down

8: electrode covering type and type of current. In this case, 8 means basic coating with iron powder added. It can be used with AC or DC electrode positive.

Flux core arc welding (FCAW)

E491T-1M-H8

E: electrode

49: minimum tensile strength in MPa/10

1: all positions

T: flux cored

1: usability and performance characteristics. In this case, single and multipass welding, and a high deposition rate

M: shielding gas 75% argon and 25% carbon dioxide

H: optional designator indicating controlled hydrogen

8: number of ml of hydrogen per 100 g of deposited weld metal