The development of welding procedures by steel shops and field welding contractors is a requirement of all welding codes. The codes intend that welding companies create welding procedures for each welding process to demonstrate that they are capable of depositing sound weldments so that metal components can transfer the loads across the joints.

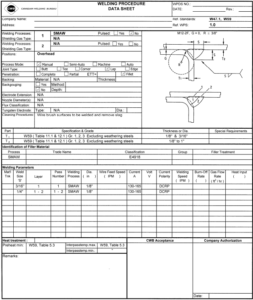

A WPDS is a summary of the key welding variables to be followed by welders. This one-page document details the welding process, base metal, joint fit-up dimensional tolerances, joint type, weld type, welding positions, welding consumables, welding parameters (i.e., amperage, voltage, travel speed), preheating and interpass temperature, and other variables to be followed. Following these variables is essential to achieve the designed mechanical and chemical properties of the shop and field welded joints.

If the field welders do not have copies of the welding procedures, the likelihood of missing an important welding variable increases exponentially. This possibility is an unnecessary risk that could lead to weld failure. Also, welding inspectors are required to review if welding contractors adhere to the welding code and follow their welding procedures. If the inspector notes that the welding procedures are missing, he can’t perform his job and will report on it.

Field welding contractors should always have copies of their welding procedures with them. It doesn’t take much to print them or have them on your phone. It also demonstrates that welding contractors have a sound quality program which is beneficial for all the parties engaged in the project.

Do you find this article useful? Feel free to share your opinion!